Are you looking for a new light for your warehouse? If so, it’s important to choose the right type of light for your needs. There are many different types of lights available, and each has its own strengths and weaknesses. In this blog, we will talk about why LED light is important for warehouse lighting.

If you are a warehouse owner and need LED light suppliers, then you can contact Besen LED. Besen LED is one of the leading LED light manufacturers in China with over 12 years of experience.

When it comes to warehouse lighting, there are a few key things to keep in mind. The type of light you choose will depend on the size of your warehouse, the tasks being performed, and the level of brightness you need.

If you are new to LED light then we recommend to read our complete guide to LED lighting & some common issues with led lighting

As the technology develops, LED light becomes more and more popular for warehouse lighting. There are many reasons why LED is a great choice for warehouse lighting:

LED lights are popular for a lot of reasons. They’re efficient, durable, and eco-friendly. LED lights use a fraction of the energy of traditional incandescent bulbs, making them a great choice for saving energy. They also last longer than other light bulbs, so you won’t have to replace them as often. And unlike fluorescent lights, LED lights don’t contain harmful chemicals like mercury. All of these factors make LED lights a great choice for eco-conscious consumers.

LED lighting is becoming more and more popular because of its long lifespan and lower energy consumption. This is great news for the environment, as it means that fewer resources will be needed to power lighting. LED lights also don’t contain any harmful chemicals, so they are better for the planet overall.

One of the main benefits of LED lighting is that it lasts much longer than traditional incandescent bulbs. LED lights can last up to 50,000 hours, which is significantly longer than the 1,000-2,000 hour lifespan of an incandescent bulb. This means that you won’t have to replace your light bulbs as often, which saves both time and money.

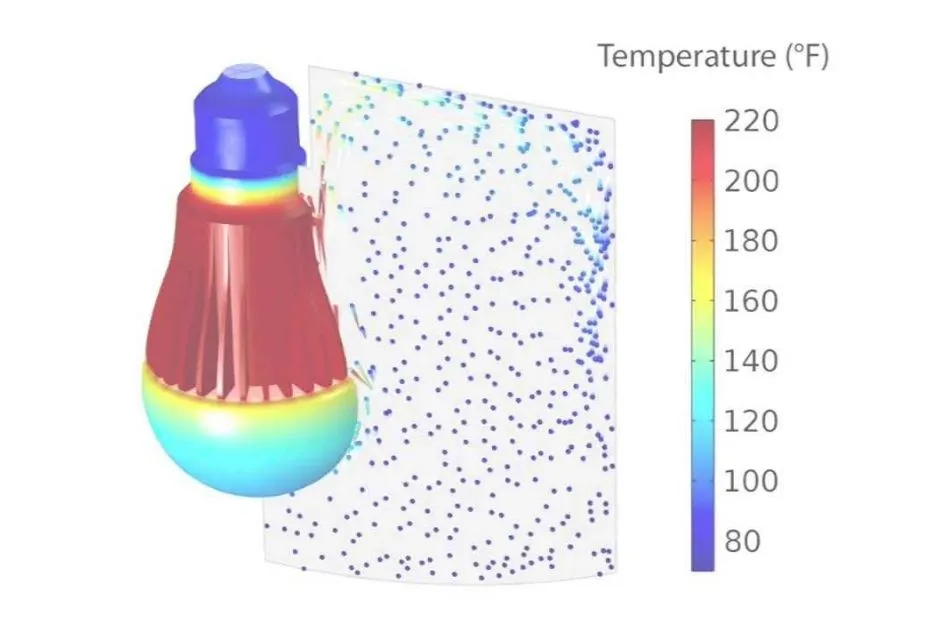

The brightness of an LED light is one of its most important features. It is important for the safety of workers in a warehouse, as well as for productivity. With traditional bulbs, a lot of energy is wasted on heat, which can make the environment uncomfortable and dangerous. LEDs generate very little heat, making them a much more efficient option.

Furthermore, LEDs are available in different brightness levels, so you can choose the right level for your specific needs. This makes it easy to create an optimal working environment without sacrificing safety or productivity.

When it comes to warehouse lighting, LEDs are a clear choice. They provide superior brightness while using less energy, making them safer and more efficient than traditional bulbs. For a brighter, safer, and more productive warehouse, choose LED lighting.

LEDs are very durable and can withstand bumps and vibrations. This makes them ideal for use in warehouses, where they are likely to be subjected to bumps and knocks. Because of its long lifespan and energy efficiency, LED light is perfect for warehouse applications. Warehouse managers can save money on their energy bills while still getting the bright, clear light they need to keep operations running smoothly. Additionally, because LED light doesn’t produce a lot of heat, it’s perfect for warehouses that need to stay cool. LED light is the future of warehouse lighting, and it’s already starting to make its way into warehouses around the country.

LED lights are known for their low heat output as compared to other light sources. This is one of the reasons why they are becoming more popular among homeowners. Compared to traditional incandescent or fluorescent bulbs, LED lights produce much less heat, making them a safer option. In fact, recent studies have shown that in some cases, LED lights can be up to 90% more efficient than other light sources.

The low heat output of LED lights is a major concern for warehouse managers. It is important to consider the impact of this on operations, workers, and products.

Operationally, the low heat output of LED light can have a significant impact on warehouse processes. For example, if the air conditioning is set to compensate for the heat from traditional light bulbs, it may not be necessary with LED lights. As a result, the AC unit could be underutilized, costing the business money. Additionally, if there is a sudden change in temperature due to an LED outage, the entire warehouse could be affected. This could lead to product spoilage or even injuries to workers.

Workers are also impacted by the low heat output of LED lights. For example, if the warehouse is particularly cold and the workers are wearing jackets, the LED light may not provide enough heat to keep them warm. This could lead to discomfort and even health issues. Additionally, if the work area is too hot due to the LED lights, the workers may be uncomfortable and less productive.

Products can also be negatively impacted by the low heat output of LED lights. For example, if a warehouse stores food products, the low heat output could cause those products to spoil more quickly. Additionally, if a warehouse stores sensitive electronic equipment, the low heat output could damage those products.

LED lightings offer high luminous efficacy and have a long lifespan in comparison to other light sources. A warehouse with LED lighting can potentially save operational costs by reducing the need for replacements, and maintenance. The maintenance cost of LED is very low as compared to other lightings. There is no need of replacing LED bulbs frequently. It can last up to 50,000 hours. So, the overall cost of using LED lighting is very low.

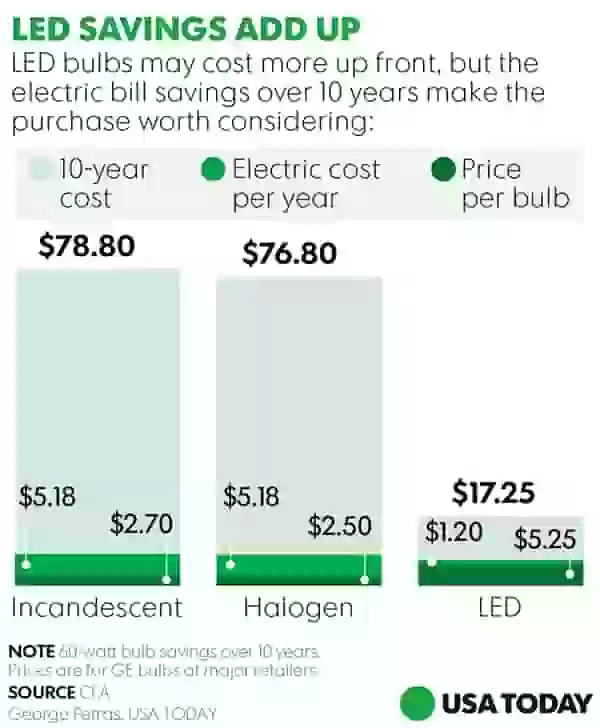

According to a research of US today LED light can save you up to $75 per month on your electricity bill.

Warehouses that have adopted LED lighting are finding that the lights offer great versatility and can be used for a variety of tasks. For example, many warehouses are using LEDs to light up aisles and help workers move around safely. In addition, LEDs can also be used to accent merchandise or create a specific mood or atmosphere in the warehouse. For example, some warehouses use blue LEDs to create a cool feeling while others use warmer colors to create a more inviting environment.

The versatility of LED lighting makes it an ideal choice for warehouses, and it is quickly becoming the standard lighting option in this setting. Thanks to the many benefits that LED lights offers, such as energy efficiency, long life span, and low maintenance costs, it is easy to see why more and more warehouses are making the switch to LEDs.

LEDs are safe to use and don’t contain any harmful chemicals. This makes them a safer option for use in warehouses. They do not produce any harmful radiation or ultraviolet light, and they are not flammable. In fact, LED lights are actually safer than traditional incandescent light bulbs, because they do not contain any mercury or other harmful materials. In addition, they don’t produce any UV or IR radiation, which could potentially cause harm to workers or products.

If your warehouse is large, you’ll need more powerful lighting than if it is small. Choose a light that will provide enough brightness for the entire space.

If your workers are performing tasks that require fine detail or precision, you’ll need a brighter light with more focused illumination. If your workers are mainly performing tasks that don’t require a lot of detail, you can choose a light that is less bright.

The level of brightness you need will depend on the tasks being performed and the type of light you choose. Make sure to choose a light that provides enough brightness for your needs.

There are a few different types of warehouse lights to choose from, including LED, fluorescent, and halogen lights. LED lights are becoming increasingly popular due to their energy efficiency and long lifespan. Fluorescent lights are also popular due to their low cost and long lifespan. Halogen lights are less common, but they provide a high level of brightness and are relatively affordable.

When choosing a light for your warehouse, keep these tips in mind. By choosing the right light, you can ensure that your workers are able to perform their tasks safely and effectively.

LED light is the best solution for warehouse

LEDs are quickly becoming the standard lighting option for warehouses. Thanks to their many benefits, such as energy efficiency, long life span, and low maintenance costs, LEDs are a great choice for this setting. They offer great versatility and can be used for a variety of tasks. In addition, LED lights are safe to use and don’t contain any harmful chemicals. This makes them a safer option for use in warehouses. For these reasons, it is easy to see why more and more warehouses are making the switch to LED lighting. Warehouse managers should consider upgrading their lighting to LEDs as soon as possible to reap these benefits.

Topic we discussed

Why LED id the best solution for warehouse lighting

Few steps to follow before choosing LED:

Product List

Quick Contact