How we control material quality

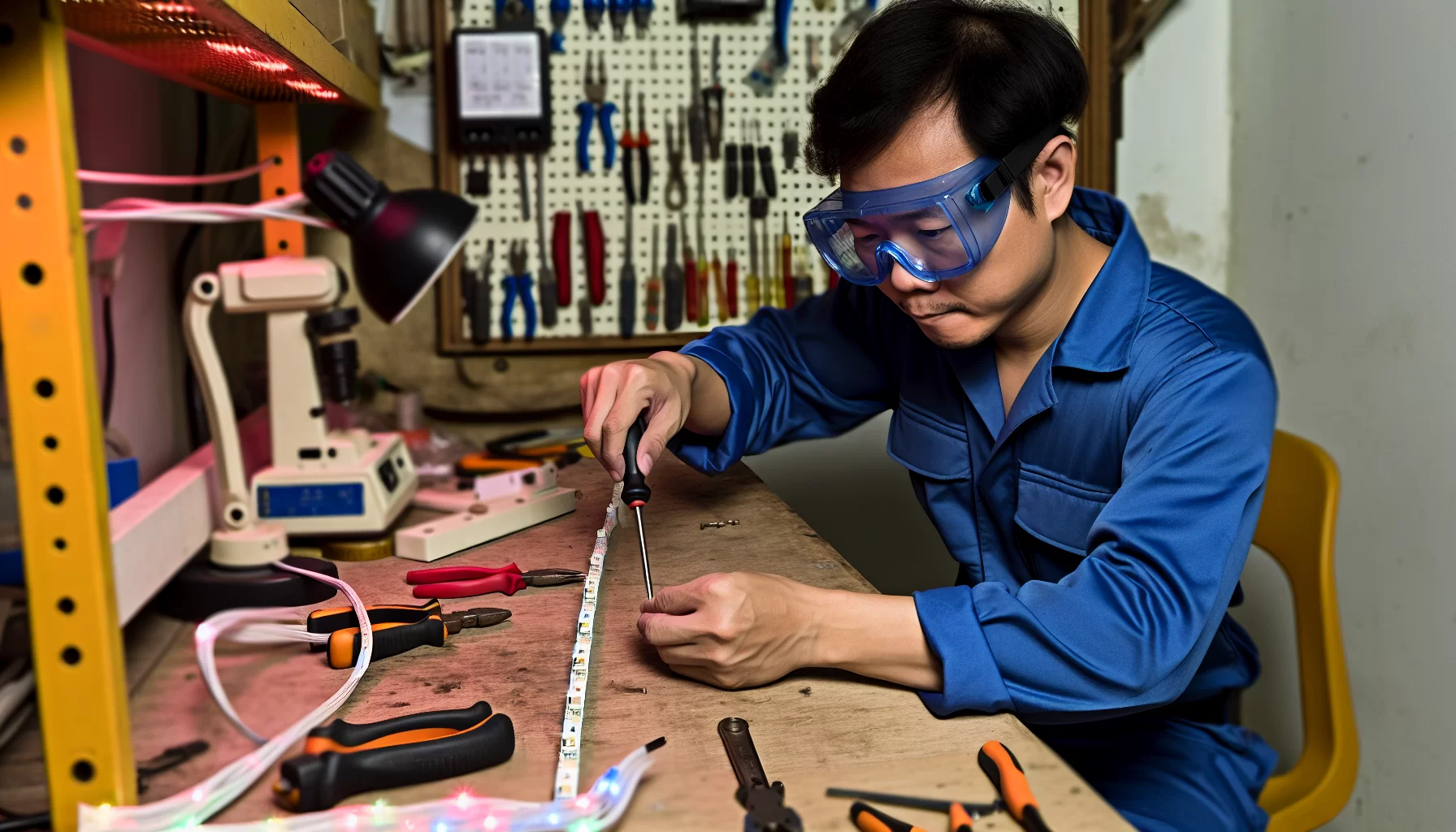

Material Control Of Smart Light

There is a science to lighting, and understanding how to control LED light material is essential to creating beautiful and effective displays. Now, we will explore the different ways that light can be controlled and manipulated. We will also discuss the benefits of using LED lights in displays and signage. By the end of this article, you will have a better understanding of how to create stunning visual effects with LED lighting!

BACKGROUND: LEDS VS TRADITIONAL LIGHTS

One of the main advantages of LED lighting is that it is much more efficient than traditional incandescent bulbs. LEDs produce very little heat, which means they use less energy and last longer. In addition, LED lights can be dimmed without reducing their lifespan, making them ideal for creating mood lighting in your home or business.

The led light material is important to the function of the light. The leds are made up of small diodes that need to be semiconductor material in order to work. One layer will have an excess of electrons and the other layer will be depleted of electrons. This difference in electron levels allows for movement between layers and creates light through electronic excitation. By understanding the led light material, you can better control the output and function of your LED lights.

If you’re interested in controlling LED lights, it’s important to first understand the materials they’re made from. LED stands for light emitting diode, which means that each individual LED is made up of a tiny diode – a semiconductor device with two terminals through which an electric current can flow.

Diodes are made of two layers of semiconductor material, one of which has an excess of electrons and the other of which is depleted of them. This difference in electron levels allows electrons to flow from the layer with more electrons (the anode) to the layer with fewer electrons (the cathode), creating light in the process through a process known as electronic excitation.

By understanding led light material, you can better control the output and function of your LED lights. For example, by controlling the amount of semiconductor material used in each diode, you can control how much light is emitted and what color it is. So if you’re looking to add some LED lights to your home or business, now you know where to start!

What are your thoughts on led light material? Let us know in the comments below!

START YOUR PROJECT TODAY WITH A FREE QUOTE

LED DESIGN

– led lights

– design

– creativity

– color temperature

– brightness

– efficiency

– manufacturing

– semiconductor material

– impurities

The first step is to understand what your application or project calls for. After that, it’s important to determine the size of light you need as well as the level of brightness and efficiency. With those factors in mind, you can begin to narrow down the type of led light material that will work best for your needs. Once you’ve selected a few options, it’s time to experiment with different colors and temperatures to see what looks best. With a little trial and error, you’ll be able to find the perfect led light material for your project!

MANUFACTURING: HOW LEDS ARE MADE

The manufacturing of LEDs is a delicate and complex matter, but we’ll do our best to sum it up

The next step is to take the semiconductor wafer and “dope” it. Doping is the process of adding impurities to the semiconductor material. This is done in order to change its electrical properties. The most common dopants are phosphorus and boron. Once doped, the semiconductor wafer is ready to. Finally, the whole thing is encapsulated in epoxy to protect it from the elements. And that’s be made into an LED.

To do this, a thin layer of p-type (positively charged) semiconductor material is deposited on top of the wafer. This is usually done with a process called “chemical vapor deposition”. The p-type material is then patterned into the desired shape using photolithography. After that, another layer of semiconductor material is deposited on top of the p-type layer. This time, it’s an n-type (negatively charged) semiconductor material.

The next step is to create electrical contact with the two layers of semiconductor material. To do this, metal wires are attached to the p-type and n-type materials. These wires are usually made of aluminum or gold. Finally, the whole thing is encapsulated in epoxy to protect it from the elements. And that’s how you make an LED.

LEDs are made from a variety of materials, but the most common ones are silicon and gallium arsenide. Silicon is the material used in most electronic devices, so it’s no surprise that it’s also used in LEDs. Gallium arsenide is a more efficient semiconductor material, so it’s often used in high-powered LEDs.

LEARN MORE ABOUT LEDS WITH

If you have more questions about LEDs, visit or FAQ page or our blog! Give us a call today at 0086-139-2494-3006 to start your LED journey!

Start your project today with a FREE quote.

We’ll get back to you in 5-10 Minutes!

Why work with us

- 10+ YEARS OF EXPERIENCE

- QUICK, EASY AND AFFORDABLE!

- 1,000S OF HAPPY CLIENTS

- SERVICES ALL AROUND THE GLOBE